Fuel control

Precise fuel control with pressure and ultrasonic probes and the ATROM fleet management system - a way to reduce the company's fixed costs.

Fuel consumption control in the company fleet

You can use estimated data or a more accurate CAN bus reading to monitor fuel consumption. However, if you want maximum precision that will translate into measurable benefits, we propose installing a fuel probe and implementing the ATROM system. The data from the survey goes directly to the company's fleet management program. Just a few clicks are enough to turn them into practical reports and summaries. For full control, you can set notifications and alerts to keep your finger on the pulse. Such fuel consumption monitoring will allow you to optimize routes, orders and business trips; it will also motivate drivers to drive economically and protect the company against abuses.

Devices

Advantages of our devices

Monitoring fuel consumption in the company fleet

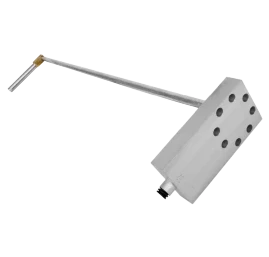

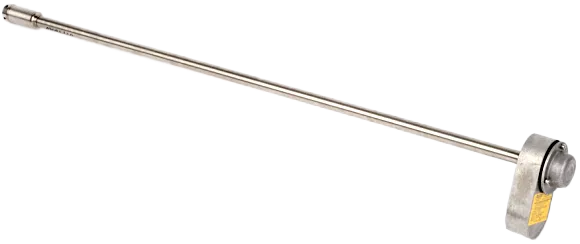

The fuel probe is available in two models: pressure and ultrasonic. The latter is used to measure the amount of fuel in diesel fueled vehicles/machines. Both probes are easy to use, and we have also provided convenient solutions, such as self-cleaning of deposits. When connected to a fleet monitoring system, they provide the ability to observe fuel combustion and control fuel in real time.

Our telematics tools are modular solutions: you decide how many and what components to include in the system. In addition to fuel consumption control, these include: settlement of drivers' working time, driver identification and temperature measurement.

Optimize, save and develop your business thanks to automatic, precise and remote control of fuel consumption in your company fleet - welcome.